Why Choose Superior Radiant (Brand) Tube Heaters?

Courtesy of: Scott Workman, Infra-Red Products Supply

SRP®’s Manufacturer’s Representative covering Utah, Idaho, Western Wyoming & Nevada.

We’re often asked “what makes Superior Radiant better than the competition?” That’s a great question since all tube heater manufacturers are equal in their intent, that is – to heat building space using the infra-red heating principle. With tube heaters, a hot flame is directed down a 4″ diameter steel tube emitter, allowing the tube to get hot, then re-directing that heat energy to the floor level via continuous parabolic reflectors over the top of the radiant tubing. This method of infrared space heating produces enhanced fuel savings and greater comfort levels compared to conventional forced air heating systems. Since infrared representatives make similar claims with regard to the benefits of infrared heat, what, then, separates one brand from another? What are their differences? What are the best criteria for selecting a particular brand?

As a manufacturers’ representative, we do our best to validate our claims with regard to the superiority of our heating products, but we do so using quantitative and qualitative data to support those claims. Those who specify infra-red tube heating systems are mainly concerned that the brand they choose will stand the test of time and provide reliable, hassle-free performance for years to come. Simply put, they want to avoid potential complaints, costly callbacks and the responsibility of remedying a problem inherent in an inferior product they themselves recommended. A little research can turn up some surprising and critical differences that can eliminate some headaches and ensure customer satisfaction.

To aid in your search for the best tube heater on the market, we offer the following:

Five Criteria for Choosing a Brand of Infrared Tube Heater:

- Reflector Design

- Heat Uniformity

- Serviceability

- Construction Quality

- Local Representation

Reflector Design

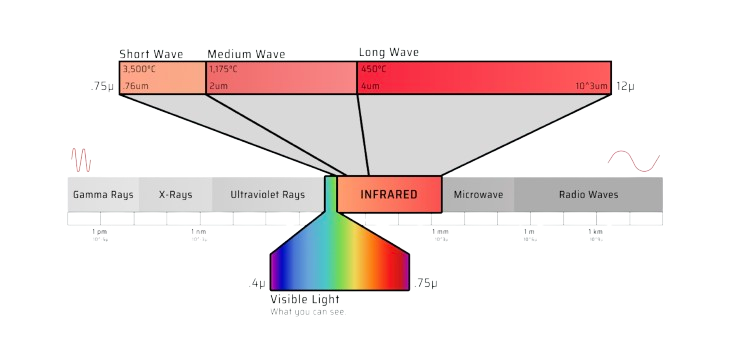

Almost all tube heaters utilize a 4″ dia. steel tube emitter. A burner on one end forces hot gases downstream through the tubes (between 10′ and 70′ in length – depending on burner size), emitting infrared “radiant” energy around its’ circumference. An optical reflector suspended over the top of the tubes is used to force the infrared energy downward. This energy is then absorbed by floors and objects below, which heat up to warm the surrounding air.

Superior Radiant has the only 10-sided reflector among all manufacturers. Its multi-faceted configuration reflects virtually 100% of the infrared energy out and away from the emitter tubes, putting that heat where it is needed – the people zone. Infrared energy “bounce-back” onto the tube is virtually eliminated and convective heat loss is minimized. Translation: more heat to the floor means less heat wasted at the ceiling – which means greater fuel savings and enhanced creature comfort. By contrast, the poorest reflector consists of a flat top with two angled sides and may have a radiant effectiveness of only 50%. The Superior reflector is also the “deep dish” style, which means that the emitter tubes are recessed up inside, with 0% exposed below the sides of the reflector. Compare some other brands which may have up to 30% or more of the tubing exposed below the bottom sides of the reflector, resulting in a high amount of energy loss into thin air that could have otherwise been reflected to the floor as usable heat energy.

An added benefit of Superior’s 100% efficient reflector design is that it helps eliminate the “hot spot” effect. That’s where back radiation of infrared energy onto the combustion tube can create excessive heat pile-up within the first several feet of the burner (where the flame is at its hottest). A poorly designed reflector can (and does on some brands) cause the combustion tube to overheat and generate thermal breakdown and eventual burn through. The remedy – expensive tube replacement in as short as 5 years, usually at the owners’ expense. Superior Radiant tube heaters have eliminated that problem.

Heat Uniformity

The ideal tube heater would generate uniform heat temperatures along the entire length of the heater. Of course, simple fluid flow physics states that heat must dissipate as it travels away from the burner. However, Superior Radiant utilizes a patented “jet stream” burner, which shoots hot gases farther downstream and distributes heat more uniformly. By contrast, poor burner designs have a “lazy flame”, whereby there is too much flame impingement on the top of the combustion tube, usually in the first 4 feet from the burner, resulting in an uncomfortable hot spot and adding to the aforementioned thermal breakdown of the tubing.

Serviceability

Ease of servicing is a primary concern with installers and building owners. Superior Radiants’ burner controls are easy to access. To service, the contractor simply loosens four screws on the sides and back of the control box, allowing the hinged service cover to hang down below it. Controls are viewable and accessible from either side of the box. Since the blower fan feeds air into a compartment separated from the pressure sensing controls, the service technician can make diagnostics while the blower fan is running. In addition, with controls isolated from the air stream, dust, moisture and other contaminants are less likely to corrode or adversely affect the operation of the heater over time. This is one reason Superior holds up so much better than other brands in such areas wash bays, cattle barns, wood shops, auto body shops and similar adverse conditions.

Construction Quality

There is no substitute for actually seeing a product up close and “kicking the tires”. This especially holds true for the variety of infrared tube heaters on the market today. Superior Radiant was founded on the principles of product quality and customer commitment. The quality of Superior tube heaters is evidenced by a regard for design detail and an upgrade of materials wherever justifiable. Early on, Superior Radiant engineers designed and tooled components by analyzing the weaknesses and strengths of other brands in the industry. Primary components of an infrared tube heater consist of the burner/control box, emitter tubes, reflectors, couplings and hangers. Let’s compare:

Superior’s burner/control box is made of heavy-duty powder coated galvanized steel. It uses the most industry-proven name-brand controls. The innovative box design and layout of controls provides easy access for service and has an attractive appearance.

While SRP® offers a complete line of emitter tubing types such as ordinary hot-rolled, aluminized and stainless steel, I have found that SRP®’s heat-treated aluminized tube offers the customer optimum cost benefits. The aluminum coating provides corrosion resistance, but its silver color is a poor absorber of heat. Therefore, Superior heat-treats the tubes to create a nice gray/black color on the inside and outside of the tubes. This process dramatically increases emissivity (the ability of the tube to emit heat outward) while maintaining corrosion resistance. Some brands may use non-heat treated aluminized which results in poorer performance. The heat-treated tubes of Superior provide the best of everything. In extremely corrosive atmospheres, Superior Radiant offers stainless steel and a special protective coating called “Silkote” to enhance life and performance.

Superior’s reflectors are constructed of 24-gauge aluminum sheet metal (aluminum having the best properties for reflectivity). The number of bends helps to make the reflector more rigid and less susceptible to warping through the heat-up and cool-down cycles. For added strength and rigidity, Superior provides two reflector support brackets for each 10′ reflector section. This is where competitors skimp! Superior reflectors stay straight and true and continue to look good over time and use. Superior tube heaters work great and look great.

Superior uses 12″ long heavy-duty double band couplings for connecting the 10′ tube sections. They cannot be over-tightened, yet they can be easily removed if the system ever needs to be re-located, unlike the couplings on some brands. In fact, Superior couplings are often used for field repairs when couplings from other brands fail.

The entire Superior tube heater is supported by heavy-duty chrome plated hangars, which are generally spaced 10 feet apart and suspended from the ceiling with chain. These rugged hangers are designed to carry the weight of the entire system and can be turned to point reflectors on a 45-degree angle if needed.

The burner, emitter tubes, reflectors, hangers and couplings are the main components of an infrared tube heater. Superior’s strengths are found in all its parts, not just one or two. While other brands may have some good points, we contend that they fall short of meeting all of the criteria specifiers and building owners want.

Local Representation

What good is a great product without someone locally to support it? Specifiers, installers and building owners want to know there is a reliable local source for information, service, design help, parts, and warranty service – when they need it. For over 38 years, Infra-red Products Supply, located in Draper, Utah, has served the western states of Utah, Idaho, Western Wyoming and Nevada. We keep a substantial supply of heaters and parts to meet customer demand. We are on hand to assist in design and application to ensure that building owners get a system tailored to the job and ensure customer satisfaction. We’re here for the long run and we’re here to help!

Scott Workman

Infra-Red Products Supply, Inc.