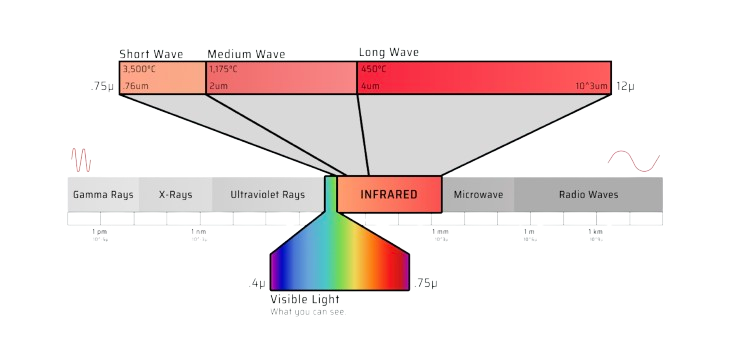

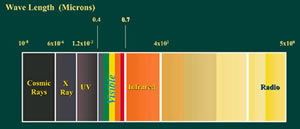

To make practical application decisions on the use of high or low intensity infrared heaters for space heating, it is helpful to have a very basic understanding of electromagnetic energy. All of the energy that we receive from the sun is broadly identified as electromagnetic (e.m.) waves to which physicists ascribe properties of wavelength and frequency.

Indeed it has been found that wavelength times frequency equals a constant which is 3 x 108 m/sec., the speed of light.

About 3% of the sun’s e.m. energy is ultraviolet or shorter in wavelength, about 50% is in the visible light band and about 47% of the energy is in infrared wavelengths and longer. It is only the infrared wavebands that supply the earth with heat energy.

All physical bodies are able to absorb and emit e.m. energy and there is a relationship between temperature, which is a measure of the heat charge of the body (as voltage is for electricity), and the wavelength of energy that the body emits. As the temperature of the emitter rises, the dominant wavelengths grow shorter and the frequency goes up.

Infrared cameras are able to receive and record e.m. energy and assign a colour on a screen to each magnitude of wavelength. The intensity and colour seen by an eye on the screen is a translation of the amount of e.m. energy of that particular wavelength measured by the camera’s receiver.

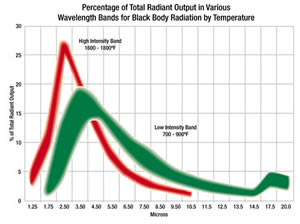

For infrared radiant heaters all of the foregoing physics principles apply. High intensity heaters, so called because the frequency band of their emitted energy is broadly higher than low intensity, operate at nominal emitter temperatures of 1600 – 1900º F. The result is that 80% of the emitted e.m. energy is in wavelengths from approximately 1 to 6 microns (10-6 meters). In practical terms, this means that the energy band is quite close to the energy band of the visible light spectrum and therefore we see the emitter as a reddish colour. The brighter the colour, i.e. tending towards orange and yellow, the shorter the average energy wavelength of the emitter.

Low intensity heaters operate in a temperature range from about 600ºF to 1100ºF with corresponding e.m. wavelengths of 2 to 10 microns. This is farther away from the visible light spectrum and therefore no light is emitted, i.e. there is no glow.

The following chart illustrates the foregoing.

eg. at 1800ºF (High Intensity Heater) 25% of the total emittance is at 2.8 microns; at 900ºF (Low Intensity Heater) 15% of the total emittance is at 4.5 microns.

In deciding on a heating appliance for a certain space, the first obvious question is; which heater, high or low intensity will perform best for me? To reach a conclusion, the broad question must be broken into several simpler questions, which we can answer on the basis of straightforward physics.

1. Does a higher radiant efficiency in a high intensity heater, i.e. the increased conversion of thermal energy to radiant energy, automatically provide improved space heating? The answer is no!

We know from the previous physics principles that as we supply more thermal energy to a given emitter, the temperature rises and likewise the average frequency of the emitted e.m. energy rises. For example, as the radiant efficiency of a given area high intensity heater is improved more and more, it produces more and more energy at the top end of its frequency band (as evidenced by a shift in colour to a brighter, whiter colour). We are also aware that white light possesses little heating qualities. An incandescent tungsten filament lamp operates at about 2000ºF and produces negligible infrared energy. The conclusion; as infrared heaters get pushed more into the luminous wavelengths, their overall infrared heating qualities actually begin to decrease.

2. Do materials absorb all wavelengths of e.m. energy in the same way? The answer is no!

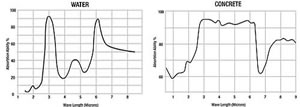

We will limit our discussion here to concrete and water as recipients of infrared energy because these are the largest heat sink constituents of a space heating application. Concrete represents the floor of the structure and water represents the human body (which is 97%, by weight, water). All elements have their own unique affinity for the absorption of certain wavelengths of e.m. energy. The following graphs are those for concrete and water.

We note that water has an affinity for wavelengths of 3 and 6 microns; concrete has an affinity for wavelengths from about 3 to 6 microns.

The obvious conclusion is that infrared heaters that produce an increasing amount or infrared energy above 3 microns, while their radiant efficiency may indeed be quite high, are producing unusable e.m. energy; energy that cannot be absorbed by the major heat sinks in the space.

3. Is installed distance a factor in preferring high or low intensity heating equipment? For all practical purposes, the answer is no!

The intensity of the output of an infrared heater is largely a function of temperature, which in turn is a measure of the heat per unit area of the emitter (we are assuming a thin emitter face). 100,000 BTUH through an emitter of 3 square feet will feel far more intense than the same output for an emitter area of 30 square feet. To release an assumed BTUH from a smaller area will require a higher temperature. The higher temperature “drives” the e.m. energy off the emitter face faster. However, as we saw previously, this will result in a generally higher frequency e.m. distribution, which may not achieve an improved heating efficiency.

As evidenced by the action of the sun, infrared energy travels through space and reaches the earth with little apparent loss. The energy can be intercepted by dust and moisture particles, e.g. clouds. Unless there are clouds in the building, the infrared energy of a high or low intensity heater of equal BTUH rating will equally reach the furthest point in the heating application.

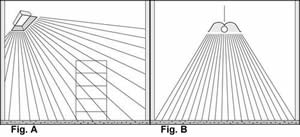

In spite of the addition of reflectors, commonly available high intensity heaters operate virtually as spot sources of e.m. energy. Figure A is representative.

A low intensity heater with a properly designed reflector will generate a heat pattern per Figure B. In good infrared space heating design, infrared radiation that impacts high up on the walls of the structure is of little use. Worse, this energy raises the skin temperature of the wall; increases the temperature gradient across the wall and increases the heat loss of the building.

4. Does the thermal efficiency rating for high and low intensity offer a good criteria for a choice between the two appliance options? The answer is no!

Thermal efficiency is an engineering criteria that can be used only with a vented appliance.

By definition of its physical design, all the thermal energy consumed by a high intensity heater remains in the building space and the thermal efficiency is therefore 100%. Low intensity infrared heaters, if vented to the outside, can have thermal efficiency percentages from the mid 70s to the high 80s. Whenever unvented heaters are used, mandated building codes require that fresh air be brought into building at the rate of 3 cubic feet per minute for every 1,000 BTUH of heat. I.e. building codes require the addition of 18,000 cubic feet of fresh air per hour for a 100,000 BTUH heater. If we assume a marginal Southern Ontario heating demand this can represent about one half of the building’s volume every hour. Regardless of individual manufacturers claims, if we regard a building and its infrared heating equipment as a total system, the “thermal efficiency of the total system” for high intensity is nearer 50% than 100% and certainly less than for a low intensity system where far less ventilation is required.